Acme screws and nuts are essential components in linear motion systems, providing precise and efficient movement. They are widely used in industrial applications due to their durability and versatility.

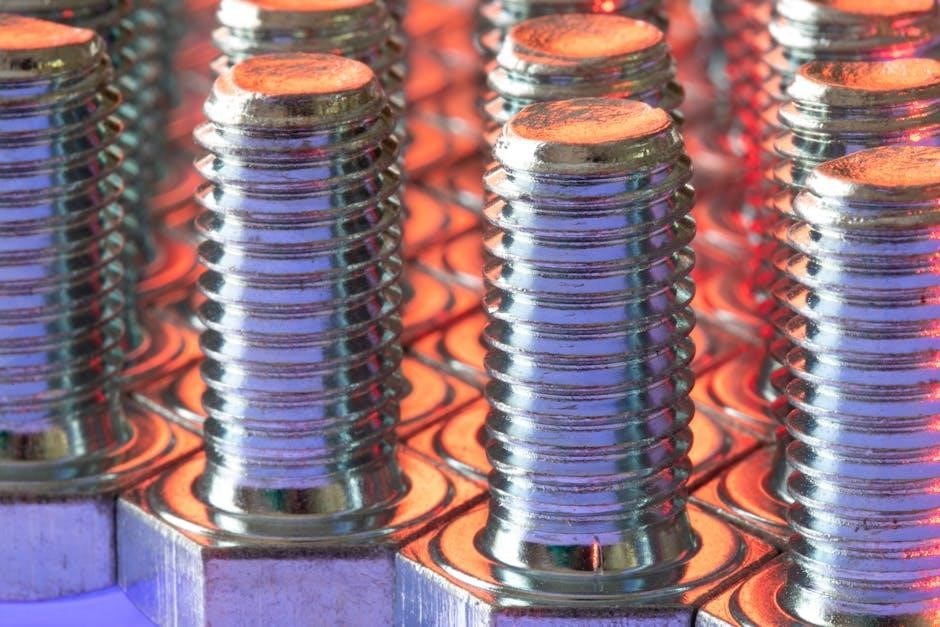

1.1 Definition and Overview

An Acme screw and nut system consists of a screw with a trapezoidal thread form and a corresponding nut. These components are designed for linear motion applications, offering high load capacity and durability. The Acme thread is characterized by its 29-degree flank angle, providing a strong and stable connection. The system is widely used in industrial machinery, actuators, and material handling systems. The design ensures smooth operation, with materials like bronze and plastic nuts offering varying levels of efficiency and noise reduction. The Acme screw and nut PDF guide provides detailed specifications and application insights.

1.2 Importance in Linear Motion Applications

Acme screws and nuts are vital in linear motion systems due to their high load-bearing capacity and precise control. They enable smooth, efficient movement in industrial machinery, actuators, and robotics. The robust design ensures durability under heavy operational demands. Their ability to handle significant axial loads makes them ideal for applications requiring consistent performance. Additionally, Acme systems are cost-effective compared to ball screws, offering a reliable solution for various industrial needs, as detailed in the Acme screw and nut PDF guide.

Acme Screw Thread Specifications

Acme screw threads are defined by parameters like pitch, major diameter, and flank angle. These specifications ensure compatibility and optimal performance in various applications, as outlined in the PDF guide.

2.1 Pitch Diameter and Major Diameter

The pitch diameter of an Acme screw is the distance between the sides of the thread at a specific pitch line. The major diameter includes the thread height and is critical for load-bearing capacity. These measurements are essential for ensuring proper thread engagement and optimal performance in linear motion systems. Accurate specifications of these dimensions are detailed in the Acme screw and nut PDF guide, ensuring compatibility and reliability in various applications.

2.2 Flank Angle and Thread Depth

The flank angle of an Acme thread is typically 60 degrees, ensuring strong thread engagement and resistance to wear. Thread depth is measured from the major diameter to the root of the thread. These dimensions are crucial for load distribution and stress resistance. The Acme screw and nut PDF provides detailed specifications, ensuring proper thread form and functionality in various applications. Accurate measurements are vital for maintaining performance and longevity in linear motion systems.

2.4 Stub Acme vs. General Purpose Acme

Stub Acme threads are designed for applications requiring a coarse pitch and shallow thread depth due to mechanical or material constraints. In contrast, General Purpose Acme threads offer finer pitches, making them suitable for high-load applications. The Acme screw and nut PDF highlights these differences, providing engineers with clear guidelines for selecting the appropriate thread type based on specific application needs, ensuring optimal performance and durability in linear motion systems.

Materials for Acme Nuts

Acme nuts are crafted from diverse materials like bronze, plastic, brass, acetal, and PEEK, each offering unique benefits such as high load capacity, noise reduction, and durability.

3.1 Bronze Nuts: Load Ratings and Wear Properties

Bronze nuts are renowned for their exceptional load ratings and superior wear properties, making them ideal for heavy-duty applications. They offer high strength, durability, and resistance to wear and tear. Bronze’s natural lubricity enhances performance in demanding environments, reducing friction and extending component lifespan. Their ability to handle high loads without deformation makes them a preferred choice for industrial machinery and linear motion systems requiring reliability and longevity. Bronze nuts strike a balance between cost and performance, ensuring optimal functionality in various mechanical setups.

3.2 Plastic Nuts: Efficiency and Noise Reduction

Plastic nuts are ideal for applications requiring high efficiency and noise reduction. They operate quietly and offer excellent performance in low-to-moderate load scenarios. Self-lubricating properties reduce friction and eliminate the need for external lubrication. Plastic nuts are lightweight, corrosion-resistant, and cost-effective, making them suitable for automation, robotics, and material handling systems. While they have lower load ratings than bronze nuts, their ability to minimize vibration and noise makes them a preferred choice for applications prioritizing smooth and silent operation.

3.3 Other Materials: Brass, Acetal, and PEEK

Beyond bronze and plastic, Acme nuts are available in brass, acetal, and PEEK. Brass offers excellent corrosion resistance and electrical conductivity, making it ideal for marine and electrical applications. Acetal provides high wear resistance and a low coefficient of friction, suitable for harsh environments. PEEK excels in extreme temperatures and chemical exposure, offering superior strength and durability. These materials cater to specialized needs, ensuring optimal performance across diverse industrial and engineering applications while maintaining compatibility with Acme screw systems.

Manufacturing Process

Acme screws are manufactured through machining or rolling processes, ensuring high precision and thread quality. These methods enable the production of screws with precise lead accuracies and durability.

4.1 Machining Acme Screws

Machining Acme screws involves precise cutting operations to achieve the desired thread form and dimensions. This process ensures tight tolerances and surface finish, critical for performance. Multi-axis CNC machines are commonly used for accuracy. The threads are typically cut using specialized tooling, such as thread mills or taps, to maintain the required pitch and flank angle. Post-machining, screws undergo quality checks to ensure compliance with specifications, making them suitable for various industrial applications.

4.2 Rolling Process for High Precision Screws

The rolling process for Acme screws offers high precision and efficiency, ideal for large-scale production. This method involves shaping the screw threads through rolling dies, enhancing strength and surface finish. It minimizes material waste and improves thread consistency. Rolled screws typically have a smoother surface and tighter tolerances compared to machined ones, making them suitable for applications requiring high accuracy and durability. This process is favored for its cost-effectiveness and ability to produce high-quality screws consistently.

Applications of Acme Screws and Nuts

Acme screws and nuts are widely used in actuators, linear motion systems, industrial machinery, and robotics. They excel in material handling and precision motion control applications.

5.1 Actuators and Linear Motion Systems

Acme screws and nuts are integral to actuators and linear motion systems, enabling precise and efficient movement. They are ideal for applications requiring consistent load handling and smooth operation. With materials like self-lubricating plastics and centralizing thread forms, these components ensure minimal wedging and enhanced performance. Their durability and versatility make them a preferred choice for linear motion control in industrial settings, providing reliable mechanical advantages for various operational demands.

5.2 Industrial Machinery and Automation

Acme screws and nuts play a crucial role in industrial machinery and automation, ensuring reliable and efficient operation. They are used in various applications, from heavy-duty manufacturing to precision automation systems. Their robust construction and ability to handle high loads make them ideal for industrial environments. Additionally, their compatibility with different materials and configurations allows for tailored solutions, enhancing productivity and reducing downtime in automated processes.

5.3 Material Handling and Robotics

Acme screws and nuts are integral to material handling and robotics, enabling precise and efficient movement. Their durability and load-carrying capacity make them ideal for robotic arms and conveyor systems. The smooth operation of Acme screws reduces noise and wear, ensuring reliability in automated systems. They are widely used in robotics for their consistent performance and ability to handle repetitive tasks, making them a cornerstone in modern material handling and robotic applications.

Advantages of Acme Screws

Acme screws offer cost-effectiveness, good lead accuracy, and high availability. They provide reliable performance and can be customized to meet specific application requirements, ensuring versatility and efficiency.

6.1 Cost-Effectiveness

Acme screws are a cost-effective solution for linear motion applications. They offer an economical alternative to ball screws, especially in lightly loaded systems. Their simplicity in design reduces production costs, making them a budget-friendly choice without compromising performance. Additionally, their availability and customization options contribute to lower overall expenses, providing a high return on investment for various industrial needs.

6.2 Lead Accuracy and Performance

Acme screws deliver consistent lead accuracy, ensuring precise linear motion in various applications. Their centralizing thread form prevents wedging, offering smooth operation. While they may have lower precision compared to ball screws, they maintain reliable performance in moderately loaded systems. This balance of accuracy and durability makes them ideal for applications where high positional precision is not critical, providing a dependable solution for industrial machinery and automation.

6.3 Availability and Customization Options

Acme screws and nuts are widely available in various sizes and configurations, making them adaptable to diverse applications. Manufacturers like Duff-Norton offer customizable options, including screw materials such as 316SS and thread directions tailored to specific needs. This versatility ensures engineers can select components that meet exact application requirements. Additionally, downloadable catalogs provide detailed specifications, enabling easy selection and integration of Acme screw systems into industrial machinery and automation projects.

Acme Screw vs. Ball Screw

Acme screws offer cost-effectiveness and handle heavy loads, while ball screws provide higher precision and lower friction, making them ideal for different industrial applications.

7.1 Performance Comparison

Acme screws excel in handling heavy loads and offering cost-effectiveness, while ball screws provide higher precision and lower friction. Acme screws are ideal for applications requiring durability and simplicity, whereas ball screws are better suited for high-precision tasks due to their lower backlash and noise. Acme screws often require more motor torque due to higher friction, but they are more economical. Ball screws, with their rolling elements, achieve smoother motion and higher efficiency, making them preferred in applications demanding accuracy and minimal vibration.

7.2 Load Capacity and Efficiency

Acme screws are renowned for their ability to handle heavy loads, making them ideal for industrial applications requiring substantial force. However, they typically operate with lower efficiency compared to ball screws due to higher friction and energy losses. Ball screws, with their rolling elements, achieve higher efficiency and smoother motion but may not match the load capacity of Acme screws. The choice between the two often depends on whether the application prioritizes load-bearing capability or energy efficiency, as each excels in different scenarios.

7.4 Noise and Vibration Characteristics

Acme screws tend to produce more noise and vibration compared to ball screws, primarily due to the sliding contact between the screw and nut. This friction-based interaction can generate audible noise, especially at higher speeds. Ball screws, utilizing rolling elements, offer quieter operation and reduced vibration, making them preferable in applications where noise reduction is critical. The choice between the two often hinges on the operational environment and the need for a smooth, quiet system versus a robust, load-bearing solution.

Acme Screw and Nut Catalog

Duff-Norton provides a comprehensive Acme screw and nut catalog, offering detailed specifications, dimensions, and application guidance. Download the PDF guide for engineers and manufacturers.

8.1 Duff-Norton Catalog Overview

Duff-Norton’s Acme screw and nut catalog offers a broad range of sizes and configurations, catering to various industrial applications. The catalog includes detailed specifications, dimensions, and application guidance, making it a valuable resource for engineers and manufacturers. It highlights the performance, quality, and delivery advantages of their products, ensuring suitability for diverse requirements. The catalog is available for free download as a PDF, providing easy access to essential information.

8.2 Specifications and Dimensions

The Duff-Norton catalog provides detailed specifications and dimensions for Acme screws and nuts, ensuring compatibility with various industrial applications. Technical details include pitch, major diameter, and thread depth, while materials like 316SS ensure durability. Customizable options, such as thread direction and screw length, are also highlighted. These specifications enable precise selection for specific requirements, ensuring optimal performance and integration into linear motion systems. The catalog serves as a comprehensive resource for engineers and manufacturers seeking tailored solutions.

8.3 Downloading the PDF Guide

The Acme Screw and Nut PDF guide is readily available for free download, offering comprehensive details on specifications, dimensions, and applications. This resource is designed for engineers and manufacturers to streamline project planning. The guide includes technical data, material options, and customization possibilities, ensuring users can make informed decisions. Downloading the PDF provides instant access to a wealth of information, enabling efficient selection and integration of Acme screws and nuts into various industrial and mechanical systems.

System Integration

Duff-Norton provides complete screw and nut systems, including mounting components, drive components, and controls, ensuring seamless integration into industrial and mechanical applications.

9.1 Complete Screw and Nut Systems

Duff-Norton offers comprehensive screw and nut systems tailored for seamless integration into industrial applications. These systems include mounting components, drive mechanisms, and protective coverings, ensuring optimal performance. They are designed to enhance efficiency and reduce installation time. With customizable options, engineers can select components that best fit their specific needs. Additionally, Duff-Norton provides technical support and services to ensure smooth system operation and longevity. These integrated solutions are ideal for actuators, linear motion systems, and automated machinery, delivering reliable and precise results.

9.2 Mounting Components and Accessories

Mounting components and accessories are crucial for securing Acme screw and nut systems. They include triangular mounts, flange adapters, and protective coverings. These components ensure proper alignment and prevent damage from environmental factors. Duff-Norton offers a range of mounting solutions designed for easy installation and compatibility with various system configurations. Accessories like end caps and wipers further enhance functionality, protecting internal mechanisms from debris. These components are essential for maintaining system integrity and performance in industrial applications.

Maintenance and Repair

Maintenance and repair services for Acme screws and nuts include refurbishment, regrinding, and replacement options. These services restore performance and extend system lifespan, ensuring optimal functionality and reliability.

10.1 Refurbishment Options

Refurbishment options for Acme screws and nuts offer a cost-effective solution to restore components to optimal condition. Services include screw regrinding, nut replacement, and surface refinishing. Inspection and assessment determine the extent of refurbishment needed. Worn or damaged parts are replaced or repaired to ensure proper alignment and functionality. This process extends the lifespan of the system, maintaining performance and reliability. Customized refurbishment packages cater to specific application requirements, providing tailored solutions for industrial and mechanical systems.

10.2 Regrinding and Replacement Services

Regrinding and replacement services are essential for maintaining Acme screws and nuts. Regrinding restores thread accuracy and surface finish, extending component lifespan. Replacement services provide new or refurbished parts, ensuring optimal performance. These services are cost-effective alternatives to buying new, tailored to specific application needs, and help maintain system reliability and efficiency in industrial settings.

Future Trends

Future trends include material innovations like high-performance plastics and smart technologies for real-time monitoring. These advancements aim to enhance efficiency, durability, and integration capabilities in industrial applications.

11.1 Material Innovations

Recent advancements in Acme screw and nut materials focus on high-performance plastics and advanced polymers. These innovations enhance wear resistance, load capacity, and self-lubrication, reducing maintenance needs. New materials like medical-grade Acetal, Ertalyte, and Turcite offer improved durability, especially in harsh environments. Additionally, self-lubricating plastics minimize the reliance on external lubricants, promoting smoother operation. These material breakthroughs are expanding the range of applications where Acme screws and nuts can be effectively utilized, ensuring optimal performance across various industries.

11.2 Integration with Smart Technologies

Acme screws and nuts are increasingly being integrated with smart technologies to enhance performance and efficiency. Sensors and automation systems now monitor screw and nut assemblies in real-time, enabling predictive maintenance. This integration allows for precise control over linear motion applications, reducing downtime and improving accuracy. Smart technologies also facilitate seamless communication between components, optimizing system performance. As industries adopt IoT, Acme screw and nut systems are evolving to meet the demands of connected, intelligent machinery.